Vakuumtrockenschrank

Die Vakuumpumpe am Trockenschrank sollte für hohen Dampfanfall ausgelegt und chemiebeständig sein. Ist für den gewünschten Trocknungsgrad eine Resttrocknung erforderlich, werden Vakuumpumpen im Bereich von 10-3 mbar benötigt.

Vakuum für Trockenschränke

Schonende Trocknung und kurze Prozesszeiten

In der Haupttrocknungsphase liegt der Druck im Grobvakuumbereich oberhalb von 1 mbar. Dabei entsteht sehr hoher Dampfanfall. Hohes Saugvermögen sowie gute Chemie- und Kondensatverträglichkeit der Vakuumpumpe sind daher entscheidend. Chemie-Membranpumpen eignen sich hierfür hervorragend.

Für manche Anwendungen ist eine anschließende Resttrocknung erforderlich, um den Trocknungsgrad zu erhöhen. Hierzu ist tiefer Druck im Feinvakuumbereich bis 10-3 mbar erforderlich. Die Schraubenpumpe VACUU·PURE ist hier die perfekte Technologie. Sie erfüllt alle Anforderungen für Haupt- und Resttrocknung.

Mit dem Vakuum-Controller VACUU·SELECT können Sie ganz einfach Zeitprogramme erstellen, um Ihren Trocknungsprozess in mehreren Stufen ablaufen zu lassen.

Wichtige Fragen zur Vakuumtechnik

Bei Prozessen am Trockenschrank entsteht ein hoher Dampfanfall. Grundsätzlich sollte die Vakuumpumpe daher ausreichend Saugvermögen im Bereich des Zieldrucks haben. Zusätzlich ist eine gute Kondensatverträglichkeit und bei Lösemitteln auch Chemiebeständigkeit erforderlich.

Zusätzlich stellt sich die Frage, ob eine Resttrocknung erforderlich ist, um den gewünschten Trocknungsgrad zu erreichen. Ist keine Resttrocknung erforderlich, eignen sich Chemie-Membranpumpen hervorragend für die Haupttrocknung. Wird eine Resttrocknung benötigt, um beispielsweise gebundenes Wasser zu trocknen, bedarf es einer Vakuumtechnologie im Feinvakuumbereich bis 10-3 mbar. Hier eignet sich die Chemie-Schraubenpumpe VACUU·PURE 10C hervorragend. Sie ist leistungsstark, chemiebeständig und hat eine ausgezeichnet Kondensatverträglichkeit. Der integrierte Regenerationsmodus ermöglicht ein schnelles Trocknen der Pumpe nach Ende des Prozesses. Der Probendurchsatz wird dadurch im Vergleich zu anderen Pumpentechnologien deutlich erhöht.

Wenn keine Resttrocknung erforderlich ist, empfehlen wir Chemie-Membranpumpen, mit einem Endvakuum im Bereich zwischen 1 und 10 mbar.

Für die Resttrocknung empfehlen wir ein Endvakuum im Bereich von 10-3 mbar. Die Chemie-Schraubenpumpe VACUU·PURE 10C ist hier die beste Wahl.

Das Saugvermögen wird anhand der zu trocknenden Probenmengen ausgelegt. Eine gute Orientierung ist dabei das Kammervolumen des Trockenschranks.

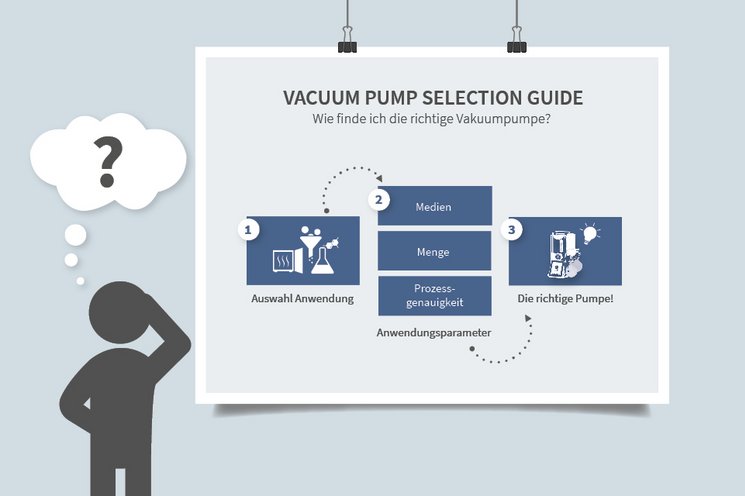

In unserem Vacuum Pump Selection Guide erhalten Sie die passenden Produktvorschläge für Ihre Anforderungen am Trockenschrank:

Präzise Vakuumregelung ist bei Trocknungsprozessen sehr wichtig, um Proben schonend zu trocknen und gleichzeitig die Prozesszeiten möglichst kurz zu halten. Einige Trockenschränke verfügen über eine integrierte Vakuumregelung. An solchen Geräten können auch Vakuumpumpen ohne Controller eingesetzt werden.

Für optimale Ergebnisse und kürzeste Prozesszeiten ist das Vakuum jedoch der entscheidende Parameter. Bereits geringe Abweichungen vom Zieldruck resultieren in deutlich längeren Prozesszeiten. Wir empfehlen daher unseren Vakuum-Controller VACUU·SELECT. Mit dessen Anwendungseditor können Sie auch ganz einfach Zeitprogramme anlegen und speichern, um Trocknungsprozesse stufenweise durchzuführen. Sie müssen nur „Start“ drücken und können sich dann anderen Aufgaben widmen.

Bei der klassischen Zweipunktregelung wird ein Saugleitungsventil geschaltet, um das Vakuum im Bereich des Zieldrucks zu halten. VARIO Membranpumpen regeln das Vakuum punktgenau über die Motordrehzahl. Diese präzisere Regelung führt zu optimalen Verdampfungsraten und Prozesszeiten. Außerdem macht es die Pumpe flüsterleise, reduziert Energiebedarf und Vibration und verlängert die Lebensdauer der Membranen.

Ein druckseitiger Emissionskondensator (EK) ermöglicht nahezu 100 % Lösemittelrückgewinnung. Ein saugseitiger Abscheider (AK) schützt die Pumpe, indem er Kondensat sammelt und Tröpfchen zurückhält.

Sowohl auf Seite der Vakuumpumpen als auch bei den Trockenschränken gibt es Modelle mit Schlauchwellenanschluss und Modelle mit Kleinflanschanschluss. Aus diesem Grund ist es nicht selten der Fall, dass sich die Anschlüsse von Pumpe und Trockenschrank unterscheiden. Für solche Fälle bieten wir Ihnen das passende Zubehör.

In unserem Connection Guide finden Sie alles, was Sie zum Anschluss Ihrer Vakuumpumpe an einen Trockenschrank wissen müssen.

ENERSENS setzt auf Vakuumtechnik für größeren Output

Es gehört zu den besten Dämmstoffen: Silica-Aerogel stammt ursprünglich aus der Weltraumforschung. Seine großen Vorzüge bestehen aus hoher Wärmedämmung bei gleichzeitig kleinem Volumen. Mittlerweile profitieren auch andere Branchen von der Superisolierung – und damit von gesteigerter Energieeffizienz, Feuersicherheit und Wärmeschutz.

Welche Vakuumregelung ist für Sie die richtige?

Auswahlkriterien für die passende Vakuumpumpe

Chemiebeständig und ölfrei bis 10-3 mbar