Rotary evaporator

Precise vacuum control is essential to achieve optimum evaporation rates and the shortest possible process times without foaming or bumping. VARIO diaphragm pumps can control the optimum pressure fully automatically.

Webinar: Vacuum for rotary evaporators

Vacuum for rotary evaporators

Precise vacuum control is key

Vacuum is the key parameter for successful evaporation, as the temperature cannot be increased at will. Precise vacuum control enables optimum evaporation rates and the shortest process times without bumping or foaming.

Aggressive media are often used. In addition, high levels of vapor can occur. The vacuum pump should therefore have good chemical resistance, high condensate compatibility and sufficient pumping speed. We generally recommend the use of a separator (AK) on the inlet side and an emission condenser (EK) on the outlet side.

VARIO chemistry diaphragm pumps with precise vacuum control and automatic evaporation mode offer the best conditions for processes on rotary evaporators.

Important questions on vacuum technology

Depending on the boiling point of the solvents, an ultimate vacuum in the range between 1 and 10 mbar is sufficient for rotary evaporation. Chemistry diaphragm pumps are best suited for this purpose. They run oil-free and offer excellent chemical resistance and durability.

With classic two-point control, a vacuum valve is switched to keep the vacuum within the target pressure range. VARIO diaphragm pumps control the vacuum precisely via the motor speed. This more precise control leads to optimum evaporation rates and process times. It also makes the pump whisper-quiet, reduces energy consumption and vibration and extends the service life of the diaphragms.

With both two-point control and VARIO control, the VACUU·SELECT controller automatically detects the boiling point of a solvent or several boiling points of a solvent mixture. VARIO diaphragm pumps also offer the option of fully automatic evaporation with boiling pressure adjustment. This means that the pressure at the boiling point is not only maintained, but also automatically adjusted to the process flow. The process runs at optimum evaporation rates, in the shortest possible time and without bumping or foaming. All you have to do is press start and then you can devote yourself to other tasks.

The ultimate vacuum required by the vacuum pump depends on the boiling points of the solvents used. Higher boiling points require a better ultimate vacuum of the vacuum pump. We recommend the following guidelines:

- up to 100 °C, two-stage chemistry diaphragm pumps with 7 mbar ultimate vacuum

- up to 150 °C, three-stage chemistry diaphragm pumps with 1.5 or 2 mbar ultimate vacuum

- above 150 °C, four-stage chemistry diaphragm pumps with 0.6 mbar ultimate vacuum

The pumping speed is determined by the quantities to be evaporated. The volume of the evaporation flask is a good orientation.

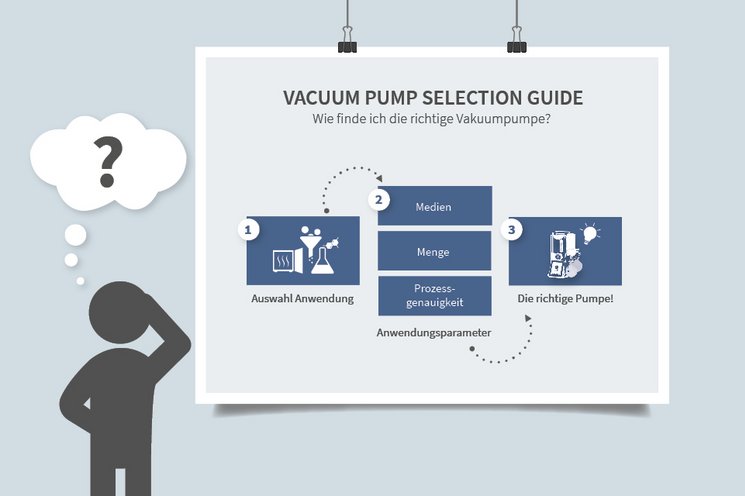

In our Vacuum Pump Selection Guide you will find the right product recommendations for your rotary evaporator requirements:

PC 520 select and PC 620 select have a second vacuum port for parallel operation on two rotary evaporators. Each vacuum port has a valve for electronic vacuum control. The integrated vacuum controller VACUU·SELECT regulates the vacuum using two-point control. Both vacuum connections are secured against mutual interference by non-return valves.

An emission condenser (EK) at the outlet enables almost 100 % solvent recovery. A separator (AK) on the inlet side protects the pump by collecting condensate and retaining droplets and particles.

Rotary evaporators and vacuum pumps usually have hose nozzle connections that are connected by a hose.

For cases in which the connection sizes of the pump and rotary evaporator differ, we offer suitable adapters as accessories.

In our Connection Guide you will find everything you need to know about connecting your vacuum pump to a rotary evaporator.

How vacuum supports rotary evaporation

Vacuum enables the evaporation of material mixtures at low temperatures and short process times. This principle is used in rotary evaporation, a fast and gentle separation process for heat-sensitive substances, among others, with different boiling points.

University of Liverpool uses innovative VACUU·LAN® solution

Which type of vacuum control is right for you?

Selection criteria for the perfect vacuum pump