Diaphragm pumps

Diaphragm pumps from VACUUBRAND are the ideal vacuum technology for many laboratory and industrial applications. Important advantages include oil-free operation, smooth running, low maintenance and a very long service life.

Vacuum Pump

Selection Guide

Do you have any

questions?

VACUUBRAND diaphragm pumps

Unsurpassed long-term performance

VACUUBRAND diaphragm pumps are known for unsurpassed reliability over many years. Thanks to their dry and completely oil-free operation, diaphragm pumps are ideal for clean processes and the production of pure products. There is no waste oil or waste water. Diaphragm pumps are therefore also particularly low-maintenance and environmentally friendly. The pumps also run very quietly, which makes them ideal for integration in devices, e.g. in analytics.

Diaphragm pumps for non-corrosive media

Clean vacuum, dry operation

Thanks to their oil-free operation and unsurpassed long-term performance, diaphragm pumps are often the first choice for laboratory and industry applications. They are also ideal as a clean backing pump for turbomolecular pumps.

ATEX diaphragm pumps

Safety through ATEX conformity

ATEX pumps are equipped with additional safety features against sources of ignition. The ATEX approval includes the inside of the pump (pumped gases and vapors) as well as the pump environment (installation location).

Vacuum Pump

Selection Guide

Do you have any

questions?

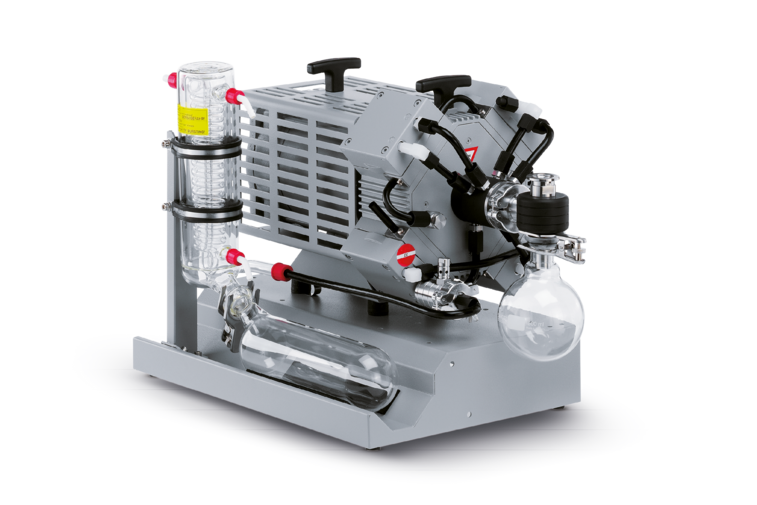

VARIO® diaphragm pumps

Smart vacuum control, efficient processes

Precise, efficient and quiet – VARIO® diaphragm pumps control the vacuum according to need via the motor speed. In combination with the VACUU·SELECT® controller, they achieve the optimal conditions for reproducible processes. The corresponding interfaces enable integration in modern laboratory networks.

OEM and built-in solutions

Customized to your requirements

VACUUBRAND diaphragm pumps are adaptable to your installation requirements: Label and color design, connections, drives and much more can be changed in the OEM variants by arrangement. VACUUBRAND has been a trusted partner for OEM solutions in the laboratory, analytical and industrial sectors for over 50 years.

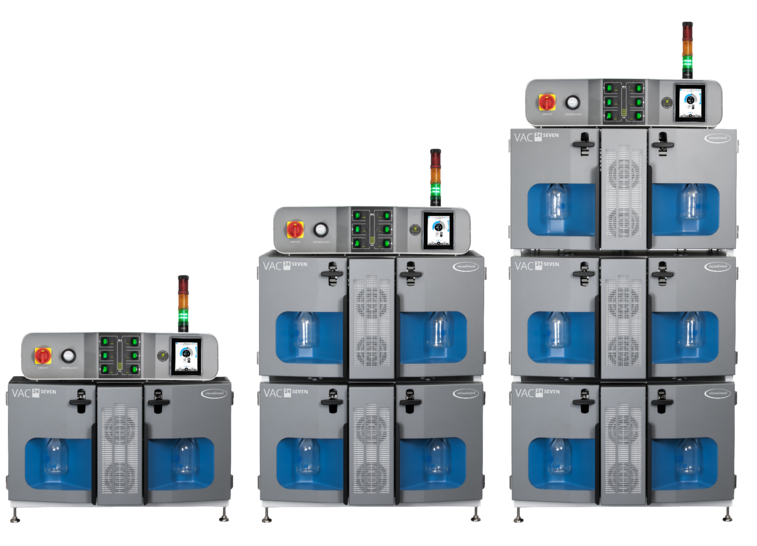

Modular process pumps

VAC 24seven - Pumping speed up to 120 m³/h

With the VAC 24seven series, the advantages of chemistry diaphragm pumps are also available on a pilot and pilot plant scale. Up to 6 pumps are combined modularly to form powerful process vacuum system.

Downloads

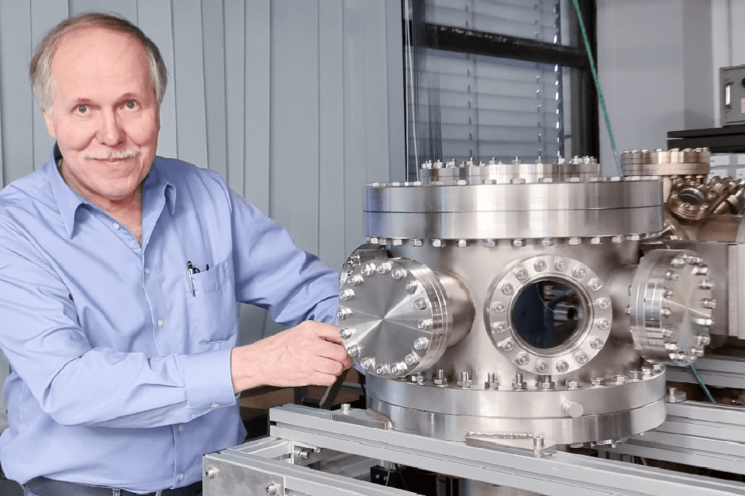

Oil-free diaphragm pumps at the Ruhr University Bochum

They eliminate 99,9 % of the unwanted gases in procedures such as molecular beam epitaxy (MBE) and focused ion beam implantation (FIB): oil-free diaphragm pumps from VACUUBRAND run continuously as fore pumps at the Ruhr University Bochum. The fore vacuum supports the generation of high and ultra-high vacuum. In this interview, we talk to Professor…

How kiteboards withstand extreme loads thanks to vacuum technology

Durable and chemically resistant MZ 2C diaphragm pump

How vacuum supports rotary evaporation

FAQ

The right connection elements and a connection which is as leakage-free as possible are important for achieving the indicated pump specifications. Use a suitable vacuum hose which offers adequate stability and does not become porous. The hose should be as short as possible and have the maximum cross-section possible. The selection of connection elements depends on your pump model and the vacuum connection of the application. We would be happy to advise you in this regard.

Condensation inside the pump impairs its function and performance and can eventually lead to damage. This problem affects both diaphragm and rotary vane pumps. Many pumps therefore have what is referred to as a gas ballast, which lets in small amounts of air or inert gas to the pump through a valve to minimizes the condensation of gases inside the pump. For many applications in chemistry, this function is indispensable for maintaining performance specifications as well as for the protection of the pump. For self-cleaning, the pump should be left to run for 15-30 minutes with the gas ballast valve open and/or the inlet open.

No, a diaphragm pump does not need any warm-up phase. However, for self-cleaning, the pump should be left to run for 15-30 minutes with the gas ballast valve open and/or the inlet open. Any condensate will be removed as a result.

We have subjected our diaphragm pumps to multi-year performance tests and determined a typical diaphragm service life of 15,000 operating hours. The parts subject to wear should be replaced after this period of time or no later than when vacuum values decrease. With VARIO control, the motor speed is adjusted based on need. As a result, maintenance intervals can be significantly increased even further.

Check the hoses and connectors for leaks. Another reason may be the formation of condensate in the pump chamber. It is therefore important to use the gas ballast when working with condensible media and to allow the pump to run for 15-30 minutes after operation. Decreasing vacuum values may also be an indication that parts subject to wear need to be changed. If this does not solve the problem, contact our Service Department. We would be happy to help you!

Contact ServiceCheck the in-line suction valve. The seal may be dirty or worn. If this does not correct the problem, contact our service department. We would be happy to help you!

Contact Service