Vacuum controller

Our versatile VACUU·SELECT® vacuum controller is ideal for applications that require precise vacuum control and reproducible processes. The intuitive operating concept ensures greater convenience and efficiency in the laboratory.

Vacuum Pump

Selection Guide

Do you have any

questions?

VACUU·SELECT

Full control over your processes

Our VACUU·SELECT vacuum controller makes your processes simple and efficient. The intuitive menu navigation is specifically designed for applications in the laboratory. Choose from predefined vacuum processes or use the application editor to create your own individual process in next to no time. For solvent evaporation, VACUU·SELECT automatically detects the boiling point and controls the vacuum process.

Complete controller

Vacuum control down to 1 mbar

Fully equipped vacuum controller for existing vacuum sources such as single pumps or powerful vacuum networks. The controller is available in several mounting configurations, as a benchtop device, for scaffold mounting or as a built-in version for panel mounting.

Packages for fine vacuum control

Vacuum control down to 10-3 mbar

For vacuum requirements in the fine vacuum range down to 10-3 mbar, the packages consisting of the VACUU·SELECT vacuum controller with fine vacuum measurement and all necessary components to enable convenient vacuum control.

VARIO diaphragm pumps

Diaphragm pumps with motor speed control

Precise, efficient and quiet - VARIO diaphragm pumps control the vacuum according to the need via the motor speed. With the integrated VACUU·SELECT controller, they create optimum conditions for reproducible processes.

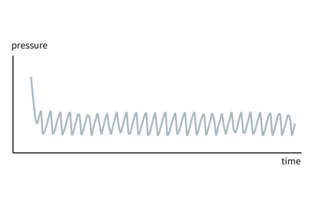

For solvent evaporation, VACUU·SELECT automatically detects the boiling pressure or several boiling points of a solvent mixture and efficiently controls the vacuum process without overfoaming. Manual regulation and monitoring of the application are completely eliminated.

Downloads

Which type of vacuum control is right for you?

Efficient integration of devices and software in Lab 4.0

VACUU·SELECT now allows added advantage of individual user permissions

FAQ

Our gauges and controllers are designed for excellent long-term stability. You should perform adjustments as required. We cannot give a general recommendation regarding the frequency. This is highly dependent on the media used in the process and the requirements for the measurement tolerances. The type of device also has an influence. Devices with capacitive sensors need to be calibrated less frequently than devices with Pirani sensors.

There is neither a regulation nor a general recommendation in this regard. As with adjustments, the need for calibration depends on the process requirements, media used and type of device. Many customers decide on six-month or annual intervals.

Yes, we operate a measurement laboratory accredited by DAkkS (Deutsche Akkreditierungsstelle GmbH) as a calibration laboratory for vacuum measuring instruments. It is authorised to perform DAkkS-calibrations for vacuum measuring instruments in the range of 1300 to 10-3 mbar (abs.) and issue DAkkS calibrating certificates.

The connections differ depending on the product. The information on this is precisely documented in the technical data and the operating manual. You can find these on the respective product page on our website or via our operating manual search.

The DCP 3000 vacuum gauge and the VACUU·SELECT vacuum controller offer the option of data logging and data transfer via RS 232 interface. VACUU·SELECT additionally offers a USB connection as well as the option of network integration and communication via Modbus TCP. For exact information on connections and interfaces, please refer to the corresponding operating manuals. You can find them on our website on the respective product page or under downloads.

In general, you can simply replace the CVC 3000 with the VACUU·SELECT controller and continue to use your existing equipment. For pumping units with a built-in controller, you should contact us in advance. We will then check whether the VACUU·SELECT fits into the housing of your existing pump.

Contact serviceWith the VACUU·SELECT user management it is possible to provide users with different rights and their own password. The user management is a paid extension.