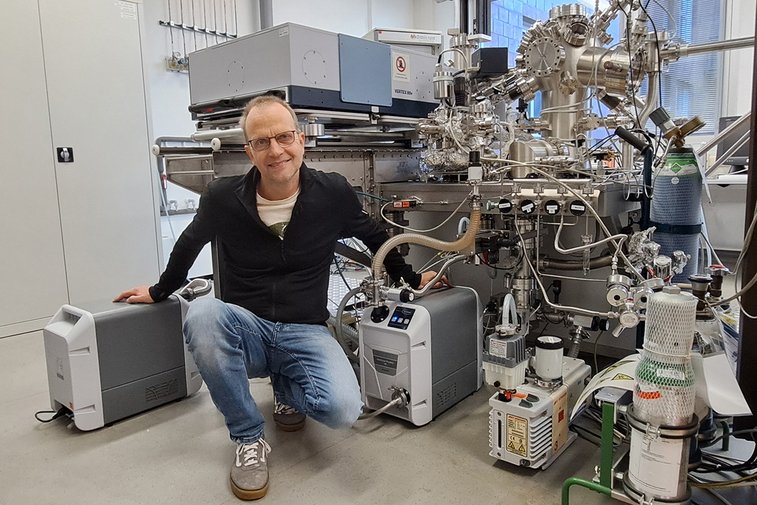

Dr. Volkmar Zielasek at the Fourier-transform infrared spectrometer and UHV system – with VACUU·PURE® vacuum screw pumps

© University of Bremen

In surface chemistry, tiny molecules can determine the success of an experiment. At the University of Bremen, researchers rely on the oil-free and abrasion-free VACUU·PURE® screw pump to create ultra-clean conditions for spectroscopy and ultra-high vacuum applications. In this interview, Dr. Volkmar Zielasek from the Institute of Applied and Physical Chemistry shares his experience with the powerful, maintenance-free technology and how it supports his research.

Dr. Volkmar Zielasek developed a passion for surface science early on as a young physicist—especially for ultra-high vacuum technology. He stayed true to his focus and joined Prof. Bäumer’s research group at the University of Bremen 20 years ago. Today, he holds a teaching appointment in physical chemistry there. The proximity to the North Sea coast suits him well, as he enjoys windsurfing.

Since we need a very clean vacuum for our experiments, vacuum pumps like the oil-free VACUU·PURE screw pump are highly important for surface chemistry. They support our fundamental research in heterogeneous catalysis, for example on sustainable energy carriers. It is advantageous to have a powerful and robust pump like VACUU·PURE that works reliably in the background—and also forgives minor operating mistakes in student use.

What is essential for surface chemistry experiments?

Dr. Volkmar Zielasek: A very clean vacuum is absolutely critical for our work. Even the smallest contaminants, such as hydrocarbons, would interfere with our experiments. That’s why we prefer oil-free pumping systems that create ideal conditions for precise investigations in surface chemistry.

At the Institute of Applied and Physical Chemistry, our team under Prof. Bäumer conducts fundamental research in heterogeneous catalysis—a field that is relevant, among other things, to the development of sustainable energy carriers like hydrogen. To this end, we prepare single-crystal surfaces and deliberately adsorb gases onto them. We track the resulting surface reactions using various spectroscopic methods and mass spectrometry.

A central element of our work is producing thin film layers as catalysts on single-crystal surfaces. A typical example is rare-earth oxides that we prepare on metals, which are of interest for the water-gas shift reaction. We also study ligand-linked platinum nanoparticles on microelectronics sensors, which are intended to be used later as hydrogen sensors. In ultra-high vacuum, we examine, among other things, their thermal stability.

How do you ensure a clean vacuum?

Dr. Volkmar Zielasek: In the past, we typically used only oil-sealed rotary vane pumps. With regular maintenance, these can be relatively durable. However, oil mist can diffuse into the vacuum chamber. We do use oil mist filters, but they slightly reduce the pumps’ suction performance.

That’s why we have also been using oil-free scroll pumps for several years. We can operate them without oil mist filters to avoid unwanted hydrocarbons. However, the seals come into direct contact with steel surfaces, which causes abrasion and thus a loss of performance. Despite replacing the seals, the pumping performance was so compromised that we had to completely replace some units after just a few years.

In our experience, both pump types require very high maintenance efforts. This includes oil changes for rotary vane pumps or seal replacements for scroll pumps. During that time, we obviously cannot operate our system—and all of this costs us money and labor.

What alternative do screw pumps offer?

Dr. Volkmar Zielasek: We are always interested in oil-free, low-maintenance pump technologies. For us, it was new and crucial that screw pumps—which are known to operate without lubricants and sealing materials—now exist in a compact design suitable for the laboratory. We hope to achieve the required pumping performance maintenance-free over many years—saving downtime and operating costs.

In a multi-week test, I was able to compare the suction performance of the VACUU·PURE model with other pump types. The nominal values were 5 m³/h for the rotary vane pump, 10 m³/h for the screw pump, and 15 m³/h for the scroll pump. However, at pressures of around 1 mbar, the screw pump already had the edge in pressure-dependent pumping performance.

At even lower pressures, it clearly outperformed both comparison pumps—in my example by at least a factor of six compared to the rotary vane pump, also because of the rotary vane pump’s oil mist filter. For our application as a forepump, where we need to reach into the 10⁻3 mbar range, the screw pump gets us to the target significantly faster. We therefore consider it a genuine alternative.

How does VACUU·PURE support the spectrometer?

Dr. Volkmar Zielasek: We use VACUU·PURE continuously on an infrared spectrometer that is purged with nitrogen. The optical chamber is evacuated to around 1 mbar. Dry operation is crucial here to ensure absolutely that no oil mist enters the instrument.

Previously, we used a scroll pump, which is generally a proven oil-free technology. However, for our continuous operation on the spectrometer, seal abrasion turned out to be a weak point, leading to downtime. The screw pump has so far been running reliably in the background, is robust against minor operating errors, and enables bachelor’s and master’s students to safely use the instrument for their projects. The spectrometer, including the vacuum valves, is conveniently controlled via a computer.

Another advantage is that the screw pump is insensitive to condensing vapors—in our case, primarily water. If a humid atmosphere needs to be pumped, the pump does not require additional gas ballast, unlike other pump types.

Is VACUU·PURE also suitable for UHV systems?

UHV system of Prof. Bäumer’s group for model studies in heterogeneous catalysis—with a VACUU·PURE® screw pump as the fore vacuum pump

© University of Bremen

Dr. Volkmar Zielasek: Yes—we actually plan to use the screw pumps on our ultra-high vacuum systems as well. For one of these systems with two vacuum chambers, we have already ordered two additional screw pumps that will be permanently installed.

What further plans do you have for the future?

Dr. Volkmar Zielasek: In the long term, we are also considering catalysis experiments under ambient conditions—i.e., independent of ultra-high vacuum. In these experiments, we introduce test catalysts into small, heatable reactors at atmospheric pressure. We analyze the products primarily using gas chromatographs in combination with mass spectrometers. For this area as well, we will certainly try to rely on the oil-free, maintenance-free technology of screw pumps in the future.

We would like to thank Dr. Volkmar Zielasek and the University of Bremen for the interview.