In permeation testing, the migration of gas molecules through materials is measured.

© AI-generated

From Mars rovers to deep-sea pipelines: Mecadi is an expert in permeation and polymers – testing barrier plastics for nearly all industrial sectors. For a quarter of a century, the company has relied on vacuum pumps from VACUUBRAND.

A vacuum pump that has been running continuously for decades – to many, that sounds unbelievable. At Mecadi, it's reality. "The MD 4C vacuum diaphragm pump has been in continuous operation for manometric permeation testing for 25 years," reports Pascal Posse, Head of Engineering. The service record during this time: one or two diaphragm or valve replacements – each completed quickly and without complications.

And this is not an isolated case. Several VACUUBRAND pumps have been running virtually around the clock for 15 to 20 years in continuous operation. A failure rate approaching zero – and a success story based on years of trust.

Pascal Posse, Head of Engineering at Mecadi.

© Pascal Posse

Pascal Posse, who is responsible for plant engineering and design at Mecadi, originally worked in the high-pressure sector. "I grew up in the hydrogen world. Vacuum technology was new territory for me at first," reports the mechanical engineer.

Since then, he has gained deep expertise: today he is responsible for engineering – and talks about the experiences his colleagues have had with VACUUBRAND over 25 years.

The reliability of VACUUBRAND vacuum pumps is immensely important for us. Sometimes we need to keep samples under vacuum for several weeks. If there were a sudden pressure increase, all the work would be for nothing. Additionally, chemical resistance is a critical factor for some of our testing areas where we also work with highly corrosive gases.

Customized permeation testing

Mecadi specializes in testing barrier materials – primarily plastics. These are required in numerous industrial sectors, from the automotive industry and medical technology to aerospace and offshore applications. The company offers both testing services and customized permeation measuring rigs. Customers include plastic and chemical manufacturers, pipeline builders, and institutes.

"What sets Mecadi apart from many other testing laboratories is its exceptional adaptability," explains Pascal Posse. In other areas such as the food industry, it is sometimes sufficient to test, for example, whether film materials are permeable to oxygen. "We, on the other hand, test numerous gases and liquids – across a comprehensive range of pressures and temperatures. There are very few companies worldwide that cover such a broad spectrum while being able to precisely adapt to their customers' needs," says Posse. At Mecadi, manometry is used as one method for permeation measuring.

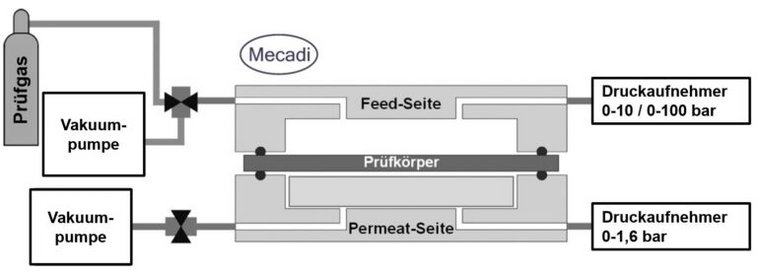

How does the testing method work?

In manometric permeation testing ("pressure rise measurement"), the gas permeability of plastics such as films, sheets, laminates, or coated materials is determined.

Setup:

- Upper chamber (feed side): The test gas (e.g., hydrogen) is applied to this chamber at the desired pressure – up to 1,000 bar at Mecadi.

- Lower chamber (permeate side): This chamber is evacuated to a vacuum of approximately 5-10 mbar for most applications. If, for example, water is still dissolved in the sample, evacuation to 1 mbar is performed to obtain a clean zero value.

Measurement:

- The test gas permeates through the material and causes a pressure increase in the evacuated chamber. The permeation rate is calculated from the pressure rise rate.

- Depending on the test pressure and material, a test can take from a few hours to several weeks.

Schematic illustration of the measurement setup for permeation determination using manometry.

© Mecadi

Hydrogen technology as a growing application field

Hydrogen technology is a particularly current topic. "This gas can permeate relatively well through various types of materials," explains Posse. "That's why we help find the most impermeable plastics, which are then used, for example, in vehicle tanks." This is where Mecadi's ability to measure at pressures up to 1,000 bar pays off – important for hydrogen applications to test under real-world conditions.

The right vacuum pump for every application

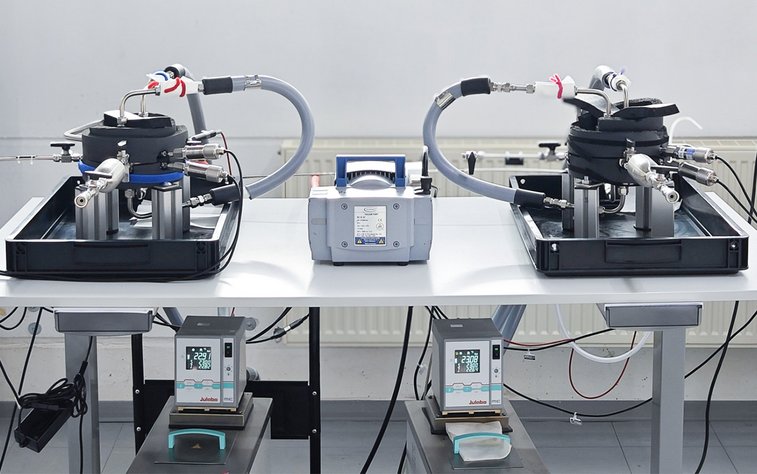

Two permeation measuring rigs are supplied by a chemically resistant MZ 2C NT vacuum diaphragm pump (center).

© Mecadi

At Mecadi, VACUUBRAND vacuum pumps are predominantly used. "For all permeation methods, we need vacuum beforehand to clean the samples, because gas is also present in the pores," explains Posse. For the actual testing methods, Mecadi uses different pump types depending on requirements, e.g., based on size, chemical resistance, or vacuum range. A vacuum of approximately 5-10 mbar is usually sufficient. Only in exceptional cases – for example, when water is still dissolved in the sample – is evacuation to 1 mbar performed to obtain a clean zero value.

In Mecadi's test rig laboratory, typically four to eight systems run simultaneously in test operation. Usually, two to three permeation measuring rigs share a common vacuum pump – made possible by the relatively small volumes. Another advantage: the pumps only need to maintain the vacuum, not continuously rebuild it – partial load operation that further extends service life.

Which vacuum pumps are used for permeation testing?

- MD 4 NT: High-performance diaphragm pump for non-critical gases (1 mbar)

- MD 1: Compact diaphragm pump for non-critical gases (1 mbar)

- MD 4C NT: Chemically resistant diaphragm pump for aggressive gases, optionally with glass waste vapor condenser for solvent recovery (vacuum down to 1.5 mbar)

- MZ 2C NT: Chemically resistant diaphragm pump for aggressive gases (vacuum down to approx. 7 mbar)

Manometric permeation testing at cryogenic temperatures with MD 1 vacuum diaphragm pump.

© Mecadi

Reliability

The duration of a permeation test depends heavily on the test pressure: at 1,000 bar, results appear in the vacuum relatively quickly; at 1 bar, a test can also take a week or longer. "If there were a sudden pressure increase during the preparatory degassing, all the work would be for nothing. The reliability of the vacuum pumps is therefore a very important criterion," explains Posse.

Chemically resistant MD 4C vacuum diaphragm pump with glass waste vapor condenser – in use for manometric permeation testing for 25 years.

© Mecadi

Chemical resistance

Another critical factor is chemical robustness. “We also work with highly corrosive trace gases such as sulfur dioxide and ammonia. For this, vacuum pumps like the chemically resistant MD 4C are indispensable.”

The situation is different for customers who purchase measuring systems from Mecadi. In these cases, the non-chemically resistant version, the MD 4 NT, is usually sufficient. "For safety reasons, many customers work primarily with non-critical inert gases such as helium, nitrogen, or oxygen. In these cases, the MD 4 NT vacuum pump is completely sufficient.

Outlook: expanding system engineering for customers

The many years of positive experience have led Mecadi to consistently integrate VACUUBRAND vacuum pumps into complete measuring systems for customers. "Every permeation measuring rig is delivered as standard with an MD 4 NT. We want our systems to run reliably at the customer's site – that's why we only use components we know work," says Pascal Posse.

Mecadi plans to expand this system engineering business even further in the future. Internally, the company is already optimally equipped. "When a vacuum pump lasts for decades, you don't need replacements very often – ideal for us, of course," Posse says with a smile. A statement that best confirms quality and reliability.