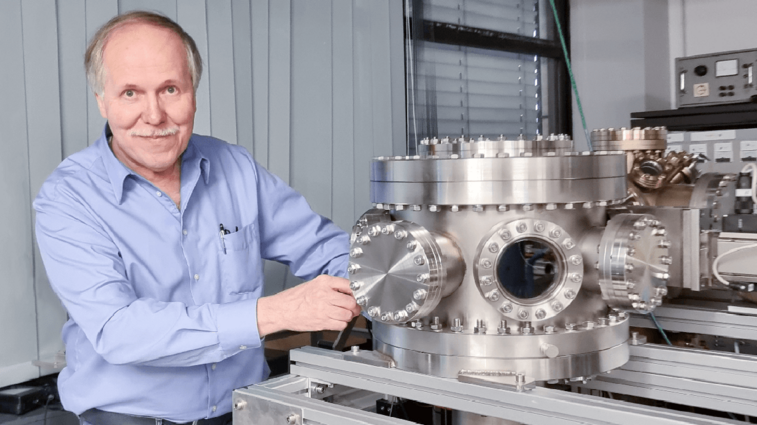

Professor Andreas Wieck's new UHV system at the Ruhr University Bochum requires a fore vacuum.

© Ruhr Universität Bochum

They eliminate 99,9 % of the unwanted gases in procedures such as molecular beam epitaxy (MBE) and focused ion beam implantation (FIB): oil-free diaphragm pumps from VACUUBRAND run continuously as fore pumps at the Ruhr University Bochum. The fore vacuum supports the generation of high and ultra-high vacuum. In this interview, we talk to Professor Andreas Wieck, Head Chair of Applied Solid State Physics.

Which vacuum technology from VACUUBRAND do you use?

Professor Andreas Wieck: I am very fond of VACUUBRAND's products, especially the diaphragm pumps. For our research, we need high and ultra-high vacuum. We have to work oil-free and therefore use dry scroll or diaphragm pumps as fore pumps. Here we use twelve units of the three-stage MD 4 NT diaphragm pump. I run my laboratory as efficiently as possible, just like a company. That's why it's important for me to use only one type of device.

What research supports this vacuum technology?

Professor Andreas Wieck: We have specialised in so-called III/V semiconductors, i.e. from the third and fifth main groups of the periodic table: essentially arsenides such as gallium arsenide, aluminium gallium arsenide and indium gallium arsenide. Soon we will also produce antimonides.

We create thin films of these semiconductors, in which we also include so-called quantum dots. My research group has become relatively well known for research on these small artificial atoms. The purpose is to be able to build novel transistors, lasers, single photon sources and diodes.

What are quantum dots?

The so-called quantum dots are nanoscopically small, half-lens-shaped crystals with a diameter of typ. 30 nm and a height of typ. 5 nm. They consist of about a hundred thousand atoms usually of one semiconductor embedded in another. Thanks to the small structure size and the confinement of the charge carriers in the quantum dot, which has a smaller energy gap than the surrounding material, quantum mechanical effects occur: Unlike conventional semiconductors, the electrons they contain are confined in all three spatial directions. Quantum dots consequently have sharp and discrete energy levels similar to that of an atom. This is why they are also called artificial atoms. In addition, they can be individually designed in terms of shape, size and number of electrons, thus leading to novel material properties. This is important for innovative components in optoelectronics, for example, such as transistors, lasers and diodes. Quantum information technology in particular can benefit from this.

Professor Wieck at an emitter maker system for filling focused ion emitters in a vacuum; MD 4 NT diaphragm pump on the right of the picture

© Ruhr-Universität Bochum

What specifically do the diaphragm pumps have to do?

Professor Andreas Wieck: We manufacture our semiconductors using molecular beam epitaxy (MBE) and focused ion beam implantation (FIB). Both processes require ultra-high vacuum and thus a sequence of different pumps:

First, we place a sample in the loading chamber. We usually pump out this chamber with a combination of fore pump and turbopump. The MD 4 NT diaphragm pump from VACUUBRAND performs the main work as a fore pump! It pumps 99,9 % of the unwanted gases out of the chamber up to approx. 1 mbar. When the pressure is then reduced to 10-6 to 10-7 mbar by the turbopump, we open a slide valve and transport the sample to the next chamber. This is then evacuated by an ion getter pump to the desired ultra-high vacuum of 10-10 or 10-12 mbar.

What do you like most about the MD 4 NT?

Durable MD 4 NT diaphragm pump for generating fore vacuum

Professor Andreas Wieck: I noticed early on that these pumps are better balanced than other manufacturers' products. I appreciate the fact that they are relatively quiet. And even though I'm a professor (laughs), I know what the pumps have to do in the lab. The diaphragm pumps from VACUUBRAND are our workhorses, so to speak, and they are excellent. We switch them on once and know that we can usually run the process for a long time and don't have to aerate in between. That's a good thing, because we simply have many other things to do in the lab. My advice for the practice: We have made the experience that running times of several years at a time are possible if we leave the cooling air flow above and below the pump unimpeded.

We would like to thank Professor Andreas Wieck and the Ruhr University Bochum for the interview.