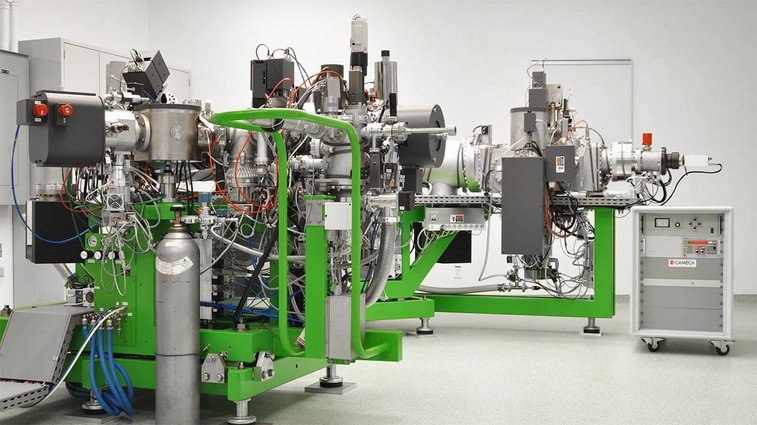

Plant for secondary ion mass spectrometry

© CCIM

At the Canadian Centre for Isotopic Microanalysis (CCIM), Dr. Richard Stern is dedicated to the study of rocks and minerals. He is the managing director of the state-of-the-art facility, which is part of the University of Alberta in Canada. The research is based on the analytical technique of secondary ion mass spectrometry (SIMS). For this, the VACUU·PURE® 10 screw pump ensures a stable and clean fore vacuum.

Dr. Richard Stern, managing director at the Canadian Centre for Isotopic Microanalysis

© CCIM

Can you tell us about yourself and your area of research?

Dr. Richard Stern: I'm at the University of Alberta in Canada and have been a research scientist here since 2008. I came here to set up a mass spectrometry lab in the center of the geoscience department. My background is in mass spectrometry and geoscience, and I've worked in the university environment and also in governments and research settings. In my specialty which is geochemistry, I support the scientists interested in minerals to better understand the rocks that they're revealing and also do my own research largely in analytical components and improving methodologies.

What is the important role of vacuum in the instrumentation?

Dr. Richard Stern: We have an instrument called an ion microprobe, which uses the analytical technique called secondary ion mass spectrometry. As for most mass spectrometry, it operates in a vacuum environment to avoid the ions colliding with molecules in the atmosphere, and therefore degrading the performance of the instrument. And so, vacuum is a prerequisite for mass spectrometry.

What are important considerations for generating vacuum?

Dr. Richard Stern: We rely on vacuum, and have to consider how we are creating vacuum, the various characteristics of the vacuum system are important elements to our work. One of those is reliability and the degree to which we can set and forget the pumping system so that we can get on with our work.

The attraction we had to the VACUU·PURE® was the lack of contact seals, which is one of the main things that causes us time and expense in maintenance dealing with ongoing seals that wear out. That was the first thing that attracted me to this technology. We also want to avoid particulates and oils that potentially could back stream into the vacuum environment, so there's a great appeal in going with an oil free pump to avoid the possibility of contamination of your vacuum by hydrocarbons in the oils.

VACUU·PURE® 10 pumping the multicollector chamber

© CCIM

How has the VACUU·PURE® been performing?

Dr. Richard Stern: We initially deployed it on an experimental basis on the benchtop giving it some tests on vacuum performance, and it performed exceptionally well. Once we completed the benchtop testing, we deployed it to one component of the vacuum system that could be isolated if there was a problem. It's really not complained once, it is very stable, both in terms of the vacuum it creates and other performance indicators. I have nothing but praise for the VACUU·PURE® in the role it contributes to mass spectrometry in our lab, it's living up to our expectations and really exceeding them.

We thank Dr. Richard Stern and the University of Alberta for the interview. The content was compiled from a video of the "Lab Days" event.