Digitalisation and automation in the laboratory market

© sdecoret - stock.adobe.com

Automation has already found its way into many areas, including the laboratory. The advantages are obvious: not only does it increase quality and productivity, but it also lowers costs and saves time. More and more users want to take advantage of these benefits. In order to automate processes in the laboratory, such as distillation, it is often necessary to coordinate the functions of devices from different manufacturers, including the VACUUBRAND vacuum pumps. Automation systems by HiTec Zang make this possible and offer easy access into the smart world of Lab 4.0. – even for those who are not familiar with automation technology.

Simple and flexible handling

With the LabManager® laboratory automation system, users network their laboratory equipment.

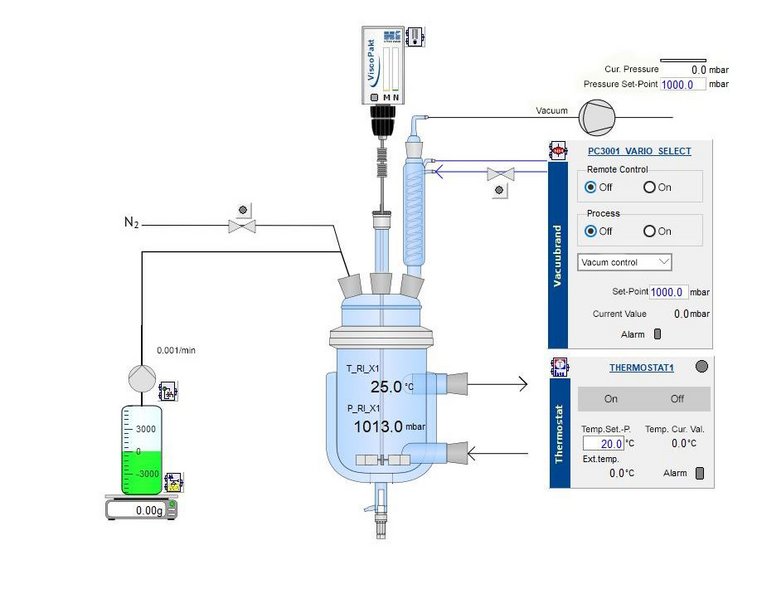

With the automation solution by HiTec Zang, users in the laboratory, pilot plant and miniplant can easily control and monitor their chemical processes even without in-depth automation knowledge. The system consists of the LabManager® laboratory automation system (see illustration for hardware) and the associated LabVision® control software.

- On the hardware side, the laboratory devices are connected to the LabManager® via a serial or Ethernet interface. This offers simple connection options for laboratory devices such as vacuum pumping units, thermostats, balances, actuators and sensors.

- With the LabVision® control software, users can visualise their processes. The connected devices can be controlled and monitored. Process parameters such as vacuum or temperature can be set and automatically logged.

HiTec Zang has years of knowledge and experience in the field of automation, especially in process control systems for production. As a result, the company also offers systems specially developed for the laboratory that are easy to use and flexible. "We enable setups ranging from small data acquisition systems to customised, complex process control systems. The simplicity and flexibility of our systems offer the advantage that after implementation, the customer can also easily develop and build the system by adding new laboratory devices himself," says Philipp Thenée, project engineer at HiTec Zang.

What are the distinct benefits of automation?

• Relieve laboratory staff of routine tasks

• GLP/GMP-compliant operation without additional effort

• Optimal process reproducibility

• Complete documentation of the entire process flow

• Shortened "time-to-market" for new products

• More efficient use of resources

• Enhanced quality, reduced risk and cost

Smart laboratory equipment for integration

Illustration of a distillation in LabVision®, with integrated vacuum pumping unit PC 3001 VARIO select

© HiTec Zang GmbH

HiTec Zang, an expert for automation and plant engineering, has been working with VACUUBRAND for many years. This enables customers to also control vacuum technology via the automation software, in addition to many other laboratory devices.

VACUUBRAND has equipped the latest VACUU·SELECT vacuum controller with the Modbus TCP interface standard so that it can communicate optimally with the control software enabling easy integration into the modern Lab 4.0.

"The VACUU·SELECT controller enables easy control of the vacuum pump. It offers a selection of predefined typical process sequences with easy parameter entry as well as the possibility to save new individual processes. Through the automation technology by HiTec Zang, these intelligent features can now be integrated and displayed in the entire process in interaction with other devices," reports Dr. Barbara Richarz, Head of Product Management at VACUUBRAND.

How can the VACUU·SELECT controller be used in automation?

• Starting and stopping the vacuum pump

• Selection of predefined or user-defined processes

• Parameter settings such as vacuum setpoints and process duration

• Export of recorded pressure data

One typical example of a Lab 4.0 use case for networked lab devices is to control a distillation process. The user in the laboratory configures his specific process, by selecting the required devices in the LabVision® software. These include devices like a thermostat, balance, magnetic stirrer as well as the vacuum pumping unit with the controller. The desired parameters for temperature or pressure curve, for example, are then entered for each laboratory device. Then the user simply starts the process, which then runs automatically, with data being logged. The processes can also be controlled remotely via the network from different locations.

Customers repeatedly confirm to us the long durability and reliable quality of VACUUBRAND products. The compact vacuum pumping units with intelligent controller also fit well into our concept of easy-to-use automation. Many customers approach us asking if VACUUBRAND equipment can be connected using our software.

Summary

HiTec Zang has mastered the balancing act between the complex requirements and intuitive operation for automation solutions. VACUUBRAND also focuses on modern work in Lab 4.0 environment with innovative products such as the VACUU·SELECT vacuum controller. Through this cooperation, both companies enable intelligent integration of vacuum generation and control into the overall process.