Vacuum drying oven

The vacuum pump on the drying chamber should be designed chemically resistant and for high vapor loads . If residual drying is required for the desired degree of drying, vacuum pumps in the 10-3 mbar range are required.

Vacuum for drying ovens

Gentle drying and short process times

In the main drying phase, the pressure is in the rough vacuum range above 1 mbar. This causes very high vapor volumes. High pumping speed and good chemical and condensate compatibility of the vacuum pump are therefore crucial. Chemistry diaphragm pumps are ideal for this purpose.

For some applications, subsequent residual drying is required to increase the degree of drying. This requires low pressure in the fine vacuum range down to 10-3 mbar. The VACUU-PURE screw pump is the perfect technology here. It fulfills all requirements for both main and residual drying.

With the VACUU·SELECT vacuum controller, you can easily create time programs to run your drying process in several stages.

Important questions on vacuum technology

Processes in the drying chamber generate high volume of vapor. The vacuum pump should therefore have sufficient pumping speed in the target pressure range. In addition, good condensate compatibility and, in the case of solvents, chemical resistance is also required.

The other question is whether residual drying is required to achieve the desired degree of drying. If no residual drying is required, chemistry diaphragm pumps are ideal for the main drying process. If residual drying is required to reach the desired degree of drying, vacuum technology in the fine vacuum range down to 10-3 mbar is required. This is where the VACUU·PURE 10C chemistry screw pump is ideal. It is powerful, chemically resistant and has excellent condensate compatibility. The integrated regeneration mode enables rapid drying of the pump after the end of the process and thus the sample throughput can be significantly increased, as compared to other pump technologies.

If no residual drying is required, we recommend chemistry diaphragm pumps with an ultimate vacuum in the range between 1 and 10 mbar.

For residual drying, we recommend an ultimate vacuum in the range of 10-3 mbar. The VACUU·PURE 10C chemistry screw pump is the best choice here.

The pumping speed is designed based on the sample quantities to be dried. The volume of the drying chamber is a good orientation.

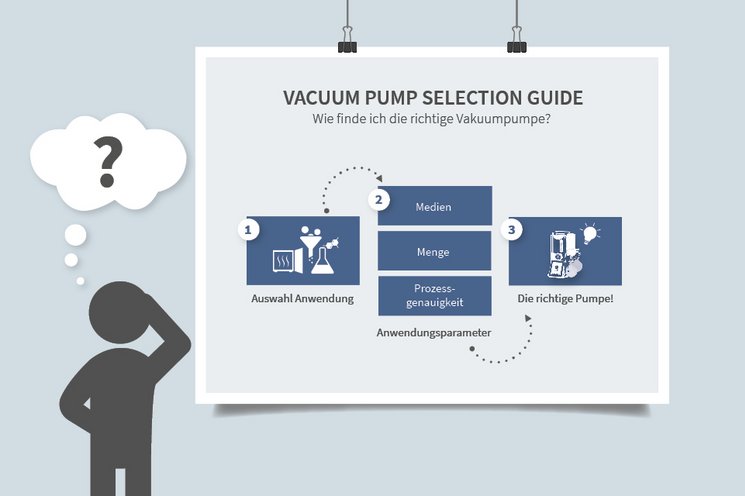

In our Vacuum Pump Selection Guide you will find suitable product recommendations for your drying oven requirements:

find pumpPrecise vacuum control is very important in drying processes in order to dry samples gently while keeping process times as short as possible. Some drying ovens have integrated vacuum control. Vacuum pumps without controllers can also be used on such appliances.

However, the vacuum is the key parameter for optimum results and the shortest possible process times. Even small deviations from the target pressure result in significantly longer process times. We therefore recommend our VACUU·SELECT vacuum controller. With its application editor, you can also easily create and save processes with multiple drying stages. All you have to do is press "Start" and you can then move on to other tasks.

With classic two-point control, a suction line valve is switched to keep the vacuum within the target pressure range. VARIO diaphragm pumps control the vacuum precisely via the motor speed. This more precise control leads to optimum evaporation rates and process times. It also makes the pump whisper-quiet, reduces energy requirements and vibration and extends the service life of the diaphragms.

An emission condenser (EK) at the outlet enables almost 100 % solvent recovery. A separator (AK) on the inlet side protects the pump by collecting condensate and retaining droplets and particles.

Both vacuum pumps and drying ovens are available in designs with a hose nozzle connection and designs with a small flange connection. For this reason, it is not uncommon for the pump and drying oven connections to differ. We offer you the right accessories for such cases.

In our Connection Guide you will find everything you need to know about connecting your vacuum pump to a drying oven.

Tips & tricks

ENERSENS relies on vacuum technology for increased output

It is one of the best insulating materials: silica aerogel originally developed from space research. Its main advantages consist of high thermal insulation combined with low density. In the meantime, other industries are also benefiting from the super insulation – and thus from increased energy efficiency, fire safety and thermal protection.

Which type of vacuum control is right for you?

Selection criteria for the perfect vacuum pump

Chemically resistant and oil-free vacuum down to 10-3 mbar