-

MZ 2C EX Chemistry diaphragm pump

MZ 2C EX Chemistry diaphragm pump- Ultimate vacuum 12 mbar

- ATEX conformity

- Oilfree & chemically resistant

-

MZ 2C EX +AK+EK Chemistry vacuum system

MZ 2C EX +AK+EK Chemistry vacuum system- Ultimate vacuum 12 mbar

- ATEX conformity

- Oilfree & chemically resistant

-

MD 4C EX Chemistry diaphragm pump

MD 4C EX Chemistry diaphragm pump- Ultimate vacuum 3 mbar

- ATEX conformity

- Oilfree & chemically resistant

-

MD 4C EX +AK+EK Chemistry vacuum system

MD 4C EX +AK+EK Chemistry vacuum system- Ultimate vacuum 3 mbar

- ATEX conformity

- Oilfree & chemically resistant

-

MD 4C EX VARIO VARIO® chemistry diaphragm pump

MD 4C EX VARIO VARIO® chemistry diaphragm pump- Ultimate vacuum 3 mbar

- ATEX conformity

- Oilfree & chemically resistant

-

MD 4C EX VARIO +AK+EK VARIO® chemistry vacuum system

MD 4C EX VARIO +AK+EK VARIO® chemistry vacuum system- Ultimate vacuum 3 mbar

- ATEX conformity

- Oilfree & chemically resistant

-

MV 10C EX Chemistry diaphragm pump

MV 10C EX Chemistry diaphragm pump- Ultimate vacuum 2 mbar

- ATEX conformity

- Oilfree & chemically resistant

-

MV 10C EX VARIO Chemistry diaphragm pump

MV 10C EX VARIO Chemistry diaphragm pump- Ultimate vacuum 2 mbar

- ATEX conformity

- Oilfree & chemically resistant

-

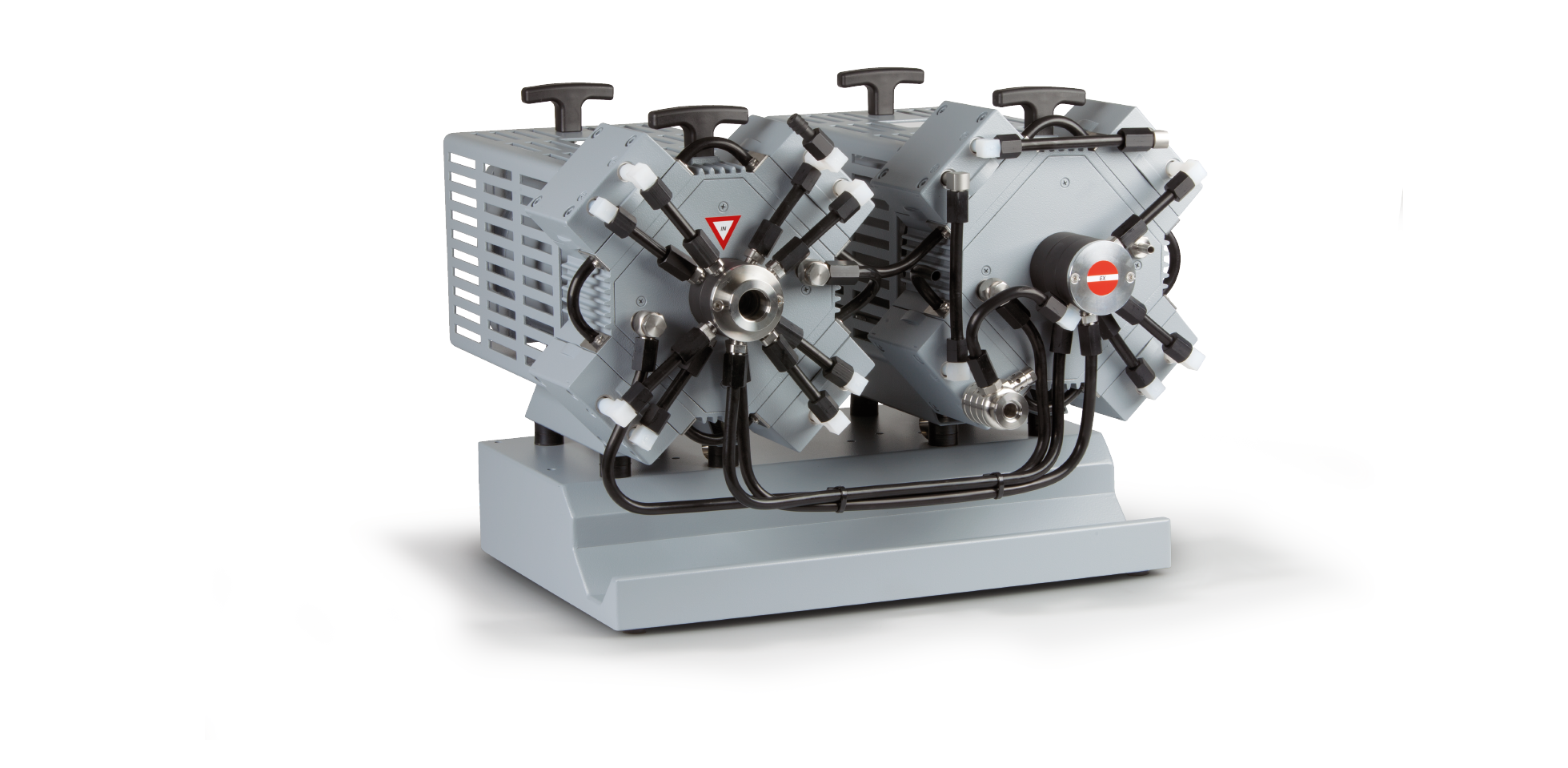

MV 10C EX VARIO +AK+EK VARIO® chemistry diaphragm pump

MV 10C EX VARIO +AK+EK VARIO® chemistry diaphragm pump- Ultimate vacuum 2 mbar

- ATEX conformity

- Oilfree & chemically resistant

-

MV 10C EX +AK+EK Chemistry diaphragm pump

MV 10C EX +AK+EK Chemistry diaphragm pump- Ultimate vacuum 2 mbar

- ATEX conformity

- Oilfree & chemically resistant

-

Connection Box 100 Connection box for ATEX VARIO pumps

Connection Box 100 Connection box for ATEX VARIO pumps- Surface-mounted insulated housing

- Pre-wired

ATEX pumps

In our store you will find the right chemistry diaphragm pump for explosive areas. Discover our offers with ATEX conformity:

- Basic models

- Variants without vacuum control

- Variants with VARIO® control

Do you have any questions about our products? We will be happy to advise you. Simply make your inquiry in the onlineshop.