High performance insulation material: silica aerogel with low thermal conductivity

© ENERSENS

It is one of the best insulating materials: silica aerogel originally developed from space research. Its main advantages consist of high thermal insulation combined with low density. In the meantime, other industries are also benefiting from the super insulation – and thus from increased energy efficiency, fire safety and thermal protection.

The French start-up ENERSENS specializes in high performance insulation products based on aerogel materials: in the form of mats, granulates and powders. In electric vehicles, for example, they prevent batteries from overheating while increasing their energy capacity. As a plaster or paint, they can eliminate thermal bridges in buildings, for example.

The company's goal is to make the super insulating material more prominent. To do this, it is breaking new ground: "We have several patents, including the use of microwaves for the synthesis and drying of aerogels. For this we have innovative R&D programmes supported by the European Innovation Council," explains David Lesueur, CTO at ENERSENS.

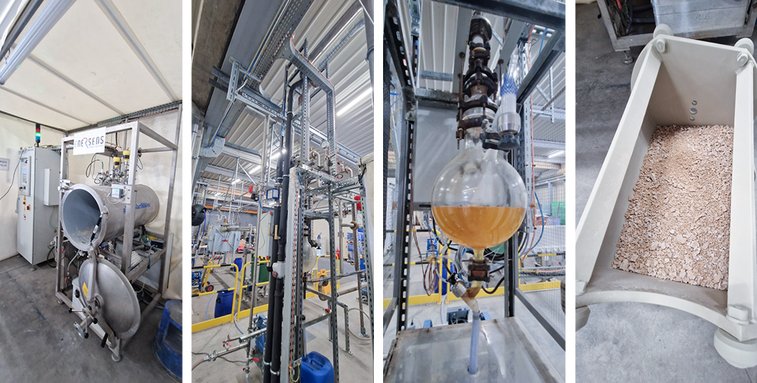

From left to right: Microwave oven, condensation column, condensate, silica aerogel

© ENERSENS

How does the special manufacturing process work? Silica gel is synthesized using a sol-gel chemistry. This induces a 95% porous structure, which is initially filled with the solvent, ethanol. However, ethanol has a surface tension that would compromise the porosity of the aerogel if it evaporates too slowly. It is therefore important to remove the solvent again by other means. Unlike supercritical drying using CO2 which is not particularly environmentally friendly, ENERSENS uses a novel method for this: a computer-controlled evaporation microwave oven operating at 915 MHz in conjunction with vacuum pumps and a three-meter-high condensation column. The plant is optimally suited for homogeneously drying large quantities of silica mass from the core to the surface.

Vacuum pumps for efficient drying

Two chemistry diaphragm pumps support the drying of silica aerogel at ENERSENS.

© ENERSENS

Another special feature: Thanks to the connected vacuum technology, the company increased the output of silica aerogel by 60 %. At atmospheric pressure and a heating power of 1 kW, only 1.25 kilograms of aerogel could be dried. Under a vacuum of 60 mbar, 2 kilograms has been achieved.

Specifically, ENERSENS uses a combination of the PC 3012 VARIO select and MD 12C NT pump models. These high-performance pumps are oil-free and require low maintenance. To extract the liquid portion of ethanol from the silica mass, a precise vacuum of 60 mbar is required in combination with a -15°C condenser. The process pumps are responsible for ensuring that this vacuum level remains constant during the drying operation. In this way, they help to maintain the high porosity and thus lightness of the material. In the end, the super insulation consists of 95 % air in 10 nm pores and has a low density of 75 kg/m3. In summary: a space-saving and highly efficient insulation material!

We need reliable vacuum technology for efficient drying of silica aerogel. For this purpose, we use the chemically resistant diaphragm pumps from VACUUBRAND. They have proven themselves in our innovative manufacturing process.