Director Marketing and Sales Bernd Jakob and Service Manager Edgar Englert during the online seminar “Connection for laboratory equipment”

The final step of connecting the vacuum pump to the laboratory device is about having the right connectors. This requires connecting parts such as small flanges and tubings. When selecting them, it is important to consider their functions, connection sizes and materials. Read our article for information and tips on how the right connecting parts contribute to smooth commissioning.

What does small flange actually mean? Small flange connections are common standard connections in vacuum technology. These are flat, round flange connections. They are available in various materials and sizes. To connect another connecting part to the small flange of a vacuum pump, you need:

- External centring ring

- Clamping ring for enclosing

- Small flange connection of another component

What functions do small flange connections have?

We offer a selection of our small flange components below. They are made of different materials such as aluminum, stainless steel or plastics (e.g. PBT = polybutylene terephthalate).

With elbow pieces you can make a corresponding direction of the connection. This is helpful, for example, if the connection of a system is at the rear, but the vacuum pump is beside it.

T-pieces provide you with an additional connection option – e.g. for another laboratory application, a vacuum sensor, a vent valve, a vacuum gauge or controller.

Cross pieces allow you four connection options at once:

1. laboratory application 2. vacuum pump 3. e.g. vacuum sensor, vacuum gauge or vacuum controller 4. e.g. vent valve for inert gas.

Valves are also available with small flanges, e.g. butterfly valves, ball valves or electromagnetic in-line solenoid valves.

Very common connection parts are small flanges with hose nozzle/nipples. You can place a flexible vacuum tubing directly onto these and, if necessary, fix it with a hose clamp.

What role do sizes play in connecting parts?

In addition to the function of a small flange component, you can also select the necessary connection size. This is important to create a tight connection. The size specification in the product name of our flanges & other small flange components refers to the inside diameter. For example, a component with the standard size "DN 16" has an inside diameter of 16 millimeters. So how do you connect the small flange tightly to the pump? The flange is inserted with the help of centring rings and both components are fixed with a clamping ring.

External centring ring:

This type of centring ring aligns the opposite connections against each other at their outer diameter. The internal sealing ring ensures a vacuum-tight connection. This gives you flexibility because the inside diameters of the two components being connected may be different. Only the outside diameter is important. You can determine this using a measuring device such as a ruler. In the example on the left, the outside diameter of the centering ring is 40 millimeters. This corresponds to a small flange of DN 25.

Centring ring:

This centring ring engages in the inner diameter of the flange. The associated sealing ring is external and thus sits outside the gas flow. It is therefore important that the two components being connected have the same inside diameter. You can determine this using a measuring device such as a ruler. In the example on the left, the inner diameter of the centring ring is approx. 28.5 millimeters. Therefore, you can conclude that it is a centring ring of standard size DN 25.

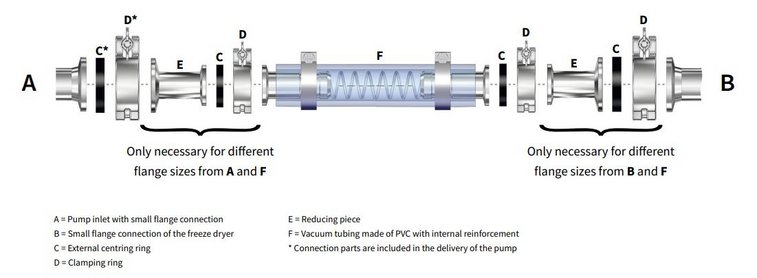

Do the vacuum connection sizes of the laboratory device and vacuum pump not match? Then you can use a reducing piece to adapt the different connection sizes.

Example of connection of vacuum pump and freeze dryer

What are the combinations of connecting parts?

Depending on the laboratory application, there are different combination options. We present these in detail in the "Connection Guide". Schematic diagrams clearly illustrate the connection between the vacuum pump and various laboratory applications:

- Freeze drying

- Vacuum drying oven

- Vacuum concentrator

- Rotary evaporator

- Filtration / solid phase extraction (SPE) / nucleic acid purification

- Fore vacuum generation for turbomolecular pumps

- Oil-free vacuum for reactors and synthesis applications

- Fine vacuum distillation

What are the advantages and disadvantages of different tubing materials?

Besides small flanges, tubings are important connecting parts. First, we would like to give you two basic tips for selecting tubing materials:

Tip 1 – Tubing diameter:

We recommend that you keep the diameter of the original connection size on the vacuum pump or system. In this way, you will benefit from the largest possible suction volume of the vacuum pump.

Tip 2 – Tubing length:

We recommend keeping the tubing connection as short as possible. This allows you to make optimum use of the possible vacuum and suction volume of the vacuum pump.

In addition, specific properties of the tubing materials can be decisive:

PVC tubing

- Cost-effective and sufficient for many applications

- Vacuum stable due to spiral inserted or integrated in the tubing wall

- Individual length due to endless tubing

Rubber tubing

- Cost effective and very flexible

- Sufficient for rough vacuum

- Other tubing types recommended for fine vacuum

Metal tubing

- Very flexible and vacuum stable

- Suitable for common solvents

- Less suitable for acids and other corrosive media

PTFE tubing

- All-rounder for many applications

- Suitable for common solvents and acids

- No outgassing thanks to smooth surfaces

Practical Connection Guide

Do you have any questions? We want to make connecting laboratory instruments as easy as possible for you. That's why we have developed the new brochure "The professional connection: With suitable connections for your vacuum pump" for you. In it you will find all the details:

- Classification according to common laboratory applications

- Connection sizes of common manufacturers

- Suggestions for pumps from VACUUBRAND

- Suggestions for corresponding connection parts

- Overview of common small flange components

The content of this blog post was compiled from an online seminar at the Lab Days event.