Filtration and solid phase extraction

Filtration usually takes place in the range around 100 mbar. A manually operated control valve with vacuum indicator is helpful for a defined flow or dripping speed.

Vacuum for filtration and solid phase extraction

100 mbar is sufficient

At a pressure of 100 mbar, 90 % of the atmospheric pressure is already available as a driving force for filtration. Further lowering the vacuum therefore has little effect on the process. Single stage diaphragm pumps are perfect for this. They do not require any operating media such as oil or water and are therefore particularly low-maintenance and environmentally friendly.

If solvents are used, chemistry diaphragm pumps are recommended. They offer excellent chemical resistance and condensate compatibility.

A manual regulator valve with manometer is helpful for a defined flow or dripping speed.

Important questions on vacuum technology

A vacuum of around 100 mbar is usually sufficient for filtration. Lowering the vacuum further has little effect on the process and can even have a disruptive effect if it causes the already filtered solvent to evaporate. Single stage diaphragm pumps are perfect for this. They do not require any operating media such as oil or water and are therefore particularly low-maintenance and environmentally friendly. If solvents are used, chemistry diaphragm pumps are recommended. They offer excellent chemical resistance and condensate compatibility.

For filtration, we recommend single stage diaphragm pumps and chemistry diaphragm pumps with an ultimate vacuum in the range between 70 and 100 mbar.

The pumping speed is determined by the size of the filtration set-up. For smaller setups up to 3-fold operation, we recommend the ME 1 and ME 1C with a pumping speed of 0.7 m3/h. For larger set-ups up to 6-fold operation, the ME 4 NT and ME 4C NT are suitable in the 4 m3/h range or the MZ 2 NT and MZ 2C NT in the 2 m3/h range.

In our Vacuum Pump Selection Guide you will find suitable product recommendations for your filtration processes:

find pumpA vacuum controller is not required for simple filtration processes. For a defined flow or drip speed, a manual regulator valve with manometer is helpful. These are available as accessories for diaphragm pumps.

If you would like to automate your filtration processes, we recommend using electronic vacuum control with the help of a vacuum controller. With the VACUU·SELECT controller, parameters such as target pressure and duration can be easily set and saved.

A separator (AK) on the inlet side protects the pump by collecting condensate and retaining droplets and particles.

The filtration assembly and vacuum pump usually have hose nozzle connections, which are connected by a tubing.

In cases where the connection sizes of the pump and filtration set-up differ, we offer suitable adapters as accessories.

In our Connection Guide you will find everything you need to know about connecting your vacuum pump to a filtration system:

Tips & tricks

Vacuum filtration as the foundation for modern analytical methods

Water is one of our planet's most precious resources, essential for sustaining life. The family-owned company Ingeniería Medio Ambiental (IMA) is an established service provider in environmental engineering and contributes to ensuring water quality with innovative analysis methods. For decades, a reliable VACUUBRAND vacuum pump has been an…

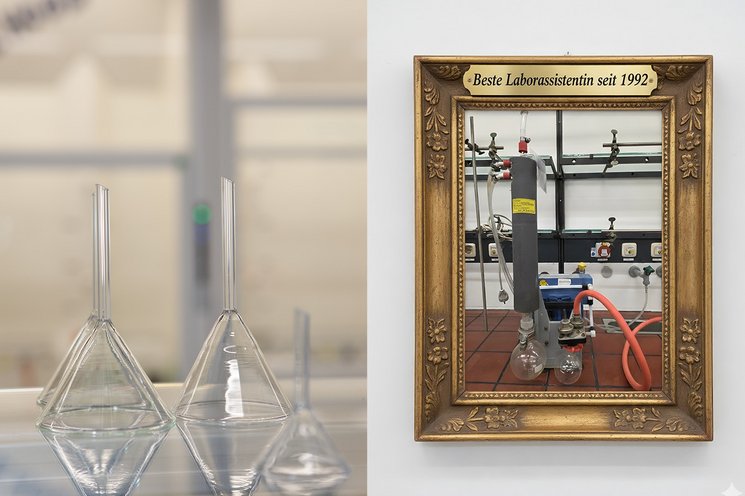

University of Göttingen uses long-life diaphragm pump for filtration

How a vacuum pump at Ruhr University Bochum became a cult device