Rotary vane pumps

Powerful and compact - these are our rotary vane pumps for a process vacuum of down to 10-3 mbar. They are designed for use in chemistry and physics, e.g. for lyophilization, Schlenk Line or as a backing pump.

Vacuum Pump

Selection Guide

Do you have any

questions?

VACUUBRAND rotary vane pumps

Powerful in the vacuum range down to 10-3 mbar

Our rotary vane pumps with comprehensive accessories are widely used in the fine vacuum range (1 - 10-3 mbar). They are designed for use in chemistry and physics, e.g. for lyophilization, distillation on the Schlenk Line, residual drying in drying chambers or as a backing pump for high vacuum pumps.

Chemistry-HYBRID pump

Effective protection against corrosion

The unique combination consists of a two stage rotary vane pump and a chemistry diaphragm pump. The diaphragm pump permanently evacuates the oil reservoir and thus frees it from corrosive vapors and condensates. This leads to significantly reduced corrosion and longer intervals between oil changes.

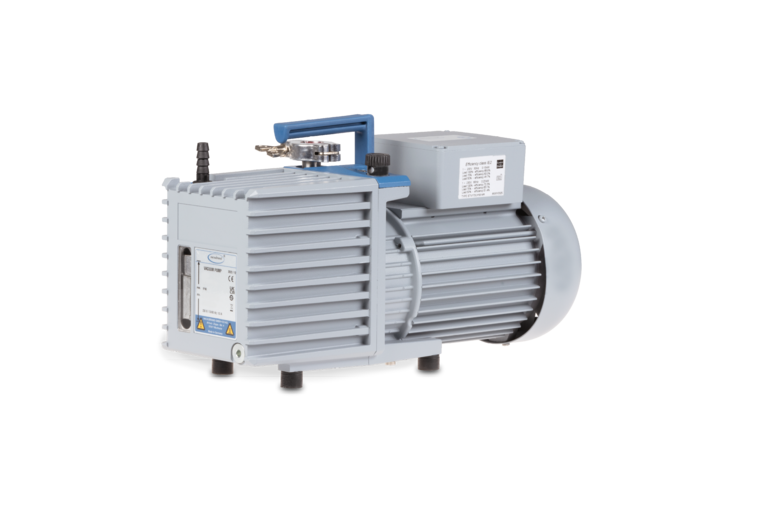

Classic rotary vane pumps

Powerful and compact

Our rotary vane pumps are known for their powerful performance. An optimized lubrication circuit and a large usable oil volume extend the oil change and maintenance intervals.

Gauges & controllers

Measure and control down to 10-3 mbar

With the VACUU·VIEW extended gauge and the versatile VACUU·SELECT® vacuum controller, we offer you first-class products for vacuum measurement and control in the range down to 10-3 mbar to pair with your rotary vane pumps.

Vacuum Pump

Selection Guide

Do you have any

questions?

FAQ

The frequency of oil changes depends on the media used. For smooth operation, it is important to check the condition of the oil regularly. A good indicator is the color of the oil. If the oil is clearly discolored, you should change the oil.

Oils for rotary vane pumps have to meet high requirements, especially in circumstances of continuous operation. Under the following link you will find our offer and information on how to choose the right oil.

Oils for rotary vane pumpsIn rotary vane pumps, many parts are made of metal and can therefore corrode when they come into contact with chemicals. In addition, the pumped gases come into contact with oil. The oil is attacked or diluted by the substances. If aggressive media are pumped, you should therefore always install a cold trap upstream to protect the pump from solvent vapors.

In principle, however, rotary vane pumps are not the optimal choice in such cases. The better alternative is the chemistry-HYBRID pump. It is the corrosion-optimized combination of a two stage rotary vane pump and a chemistry diaphragm pump.

The most suitable pump for working with aggressive chemicals in the fine vacuum range down to 10-3 mbar is the VACUU·PURE 10C screw pump. It is not only chemically resistant, but also operates oil-free.

Condensation inside the pump impairs its function and performance and can eventually lead to damage. This problem affects both diaphragm and rotary vane pumps. Many pumps therefore have what is referred to as a gas ballast, which lets in small amounts of air or inert gas to the pump through a valve. This minimizes the condensation of gases inside the pump. For many applications in chemistry, this function is indispensable for maintaining performance specifications as well as for the protection of the pump. For self-cleaning, the pump should be left to run for 30 minutes with the gas ballast valve open and/or the inlet open.

The correct connection between the pump and the application is important to obtain the best possible ultimate vacuum and pumping speed. Make sure that the connections are as short as possible and have the highest possible line cross-section. Use leak-tight small flange connections and suitable hose material that will not become porous. You can use a suction-side separator as additional protection against particles. The choice of connection components depends on your pump model and the vacuum connection of the application. We will be happy to assist you.

For long service intervals and a long service life of your rotary vane pumps, you should consider a few aspects during operation, care and maintenance. We have summarized these for you clearly on one page:

Tips & tricks